I have finally gone to a “real” crimper, even though it wasn’t cheap. Formerly Paladin and now Greenlee:

https://www.bhphotovideo.com/c/product/1548367-REG/greenlee_pa8000_crimpall_crimp_tool.html

Get the RJ45 crimp dies separately unless you can find them included. I originally got mine from Newegg including the dies. Amazon.com

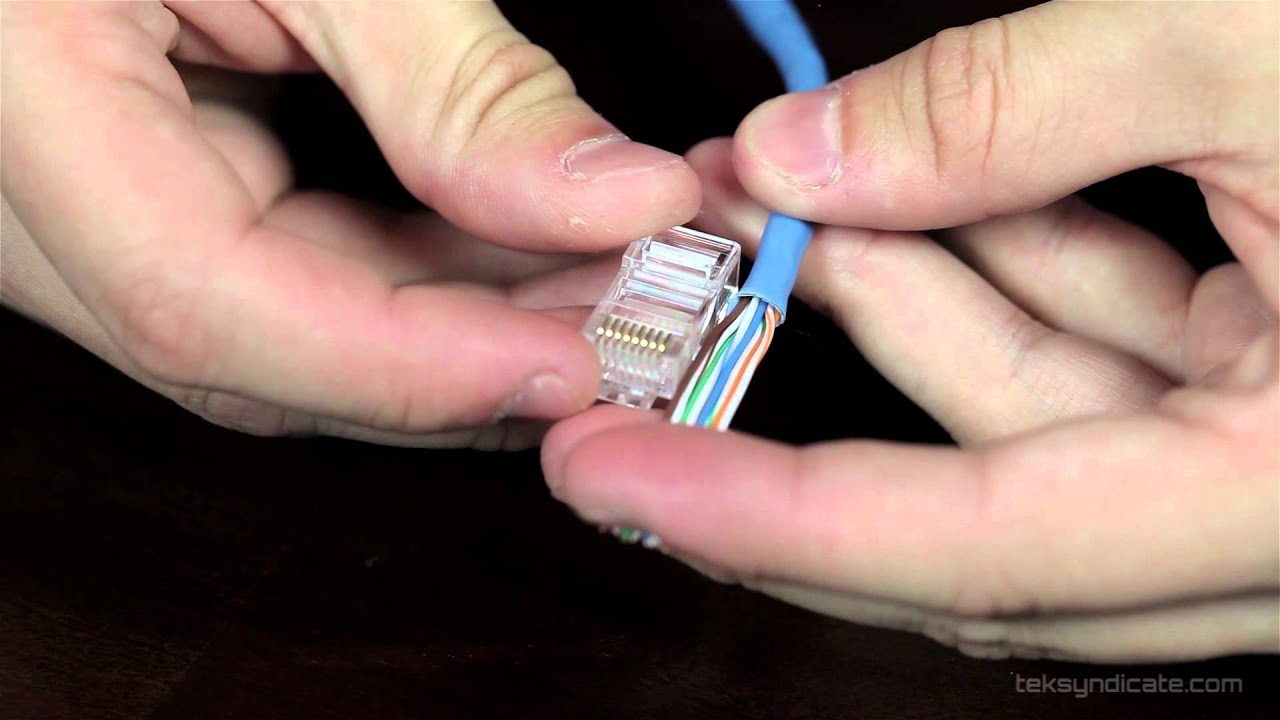

Note that the above DOES NOT work with the pass through style of connectors, I don’t use that style because I think there is too high a risk of a short from the trimmed end. Lots of people like them though so use what works for you. After thousands of connectors, there really isn’t a speed or convenience issue from the “traditional” connectors.

I have two cable devices that I can use, one I bought, one that work bought bought.

Cheapo is essential this same product, but it only cost $15 so look around https://www.newegg.com/p/1W9-0023-000A1

You need one with cross and short indicators.

The “good” one is 10+ years old so good may be a stretch but still a current product. Don’t use it much anymore as the cheapo gives me most of what I need in a hurry.

I’m looking at upgrading my personal cable checker/certifier/identifier but not yet ready to drop the money on something really appropriate.

Punch down tool : https://www.lowes.com/pd/IDEAL-Phone-Data-Punch-Down/3196707

I have a variation of this tool, they keep changing the design. I’m also building tips for some of the audio patch panels we use.

keystone jack helper: https://www.showmecables.com/keystone-jack-punchdown-holder

I bought mine from Cables and Kits, I like their service and prices are normally pretty low… This thing makes the job of punching Keystone style jacks tolerable. And yes it will spread out the force so that your “probably” won’t dent your sheetrock. Notice the word probably, but I’ve had good luck in this area.

Strippers: The only ones I’ve used are a utility knife on most cables, or the included stripper and wire separator that came with my bonded pair Belden 10GX cable (Cat7?) 10gb rated cable. It has a hook with a partially exposed blade that you can swing around with your finger and it just strips the jacket and does it perfectly every time. Not so good on thinner Cat5e or 6a cables, but I keep them around. Care MUST be taken when using a utility knife, if you nick the conductors, cut it back and try again! You DO NOT need to cut clean through the outer jacket. Just score it and fold it over, it will break cleanly without risk of nicking the copper.

![]()